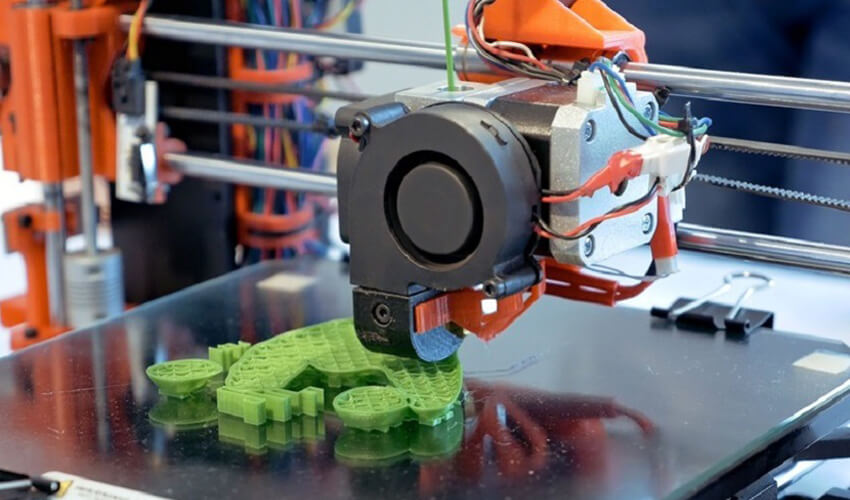

Simple about the complex. Fluidity. Let's break down this concept and see how to apply this knowledge in 3D printing.

By definition, fluidity is the mass of polymer in grams extruded through a capillary at a certain temperature and pressure drop in 10 minutes. The fluidity value for various polymer materials is determined at different loads and temperatures. In simple terms, if we consider the printer nozzle as a capillary, and the temperature and pressure created by the heating element and feeding mechanism correspond to the parameters at which fluidity measurements are taken, then fluidity is the mass of the model that was printed for 10 minutes. The fluidity value ranges from 0.3 to 3.7 grams/10 min. for extrusion grades and from 36 to 54 for molding grades. Since the same polymers are used for filament production as in other industries, we have the same fluidity properties for 3D printing.

How does fluidity affect 3D printing? Very simply: a polymer with a lower fluidity value under the same conditions will be more difficult to extrude through the nozzle, which can lead to slight under-extrusion. Conversely, if the polymer fluidity is high, under the same printing parameters, there may be more material than necessary for the model.

You can adjust fluidity in the slicer. For example, in Cura 3D, the flow setting is responsible for this parameter. It's also worth understanding that fluidity, as a polymer property, is an absolute value, a specific number. The fluidity parameter in the slicer is a relative value and changes in percentage. Adjust this parameter within small limits: for tests, add or subtract a couple of units from the default value (usually 100%). By the way, the flow parameter in the slicer is responsible not so much for fluidity as a physical parameter of the plastic itself, but for correcting inaccuracies in the printer's operation. For example, the flow parameter can correct the inaccurate operation of the Z-axis movement motor. Therefore, the value of this parameter is made relative. More information about the flow parameter and examples of its use can be found in the original slicer instructions.

Recent post